PET Molecular StructurePET (also named PETE) is a kind of polyester material for fiber, injection molded parts, as well as blow-molded bottles and jars. Special grades are offered with the required properties for the different applications.

PET is linear thermoplastic (long-chain molecule consists of repeating units shown as figure right), white but bluish resin made from terephthalic acid and ethylene glycol through poly-condensation. PET is supplied by the resin manufacturers in the form of small pellets, each about 0.05 gram. PET came into prominence in the 1950s as a textile material. Its strength, temperature tolerance and wear-resistance made it an ideal replacement for, or addition to natural fibers such as silk, cotton and wool.

It has good antiosmosis, low water absorbability and good toughness. PET film's tensile strength is similar with aluminum film's, and is three times that of PC and PA film. PET film is transparent. It's tensile strength can reach 1/3~1/2 of steel's if dealed by oriented draw. It's the toughest thermoplastic film. It will be burnt with yellow flame and will burst when burning. And it will continue burning when away from fire.

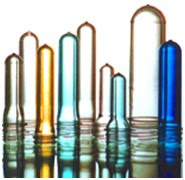

Bottle Grade PET:-

PET is still widely used for these purposes, but when, in the 1970s a marketing need was identified for larger light-weight, unbreakable bottles to contain carbonated drinks, PET fit the bill perfectly. Unlike simple polymers such as polyethylene, PET is not made by a single stage process, but by the reaction between two chemicals, purified terephthalic acid (PTA) and ethylene glycol (EG). The availability of the first of these has dictated the supply of PET resin in the past, but new capacity coming on stream this year will ensure more than adequate supplies to meet the growing uses of PET over the coming years. Related polyesters are polybutylene terephthalate (PBT) used mainly for engineering applications, and polyethylene naphthalate (PEN). The latter offers significant performance improvements over PET, particularly in terms of barrier properties and heat tolerance. Since PEN can be blended with PET a range of new 'alloys' is becoming available for special packaging applications.

As

is a kind of transparent, wear-resisting and corrosion-resisting plastics with high strength and smooth finish, it is widely used for PET bottles of mineral water, juice, edible oil, pharmaceuticals, cosmetics, etc.

- Melting Temperature: 254-2560C

- Density: 1.38~1.40g/mm3

- Glass Temperature: 820C

In the bottle industry, the length of the PET chains is usually

described by the resin IV (Intrinsic Viscosity). Bottle grades have IV

values of about 0.65 to 0.85 dL/g, or about 100-155 repeating units per

chain.

Most bottle grades of PET are copolymers, which means that

a few percent of a modifier has been incorporated into the polymer

chain. Copolymers are easier to injection mold because the crystallinity

behavior is improved.

A remarkable transformation takes place when injection molded PET is stretched at the right temperatures and to the right extent. The long chains undergo strain-hardening and strain-induced crystallization, which gives the properly-made PET bottle exceptional clarity, resistance to internal pressure, uniform wall thickness, toughness, and a host of other features. To achieve these useful properties, however, care must be taken in choosing the right grade of resin, as well as the right preform and bottle designs, and good molding practices.

Some grades of PET have other modifications to improve the bottle barrier properties, the reheat characteristics (for two-stage systems), or the generation of AA (acetaldehyde).

Main Advantage of PET :-

Crystal Clear:-

Products look good, pure and healthy. Sparkling PET bottles attract attention. Brilliant glass-clear presentation of your products.

Pure:-

Products taste good. PET complies with international food contact regulations.

Safe:-

PET bottles are tough and virtually unbreakable during production, storage and transportation. If they do fail, they split, not shatter. Their high impact and tensile strength makes them ideal for carbonated products.

Good Barrier:-

The low permeability of PET to oxygen, carbon dioxide and water means that it protects and maintains the integrity of products giving a good shelf life. PET also has good chemical resistance.

Lightweight:-

10% weight of an equivalent glass pack, PET bottles reduce shipping costs by about 30%, and because the material in the wall is thinner, shelf utilization is improved by 25% on volume compared to glass. High strength, low weight PET bottles can be stacked as high as glass.

molding machines could be divided into two categories - those using the One-Step "hot preform" method and those using the Two-Step "cold preform" method.

The One-Step method -- from PET granule to finished bottle -- all processes are completed on one integrated machine. This means the injection-molded preform is withdrawn from the injection cavity while still hot enough to be stretch blown to form the bottle. No extra heating is required, and since preforms are not stockpiled to be blown at a later date, but are freshly molded every time, there is no risk of surface damage from preforms knocking together during storage or transportation. One-Step method is highly suited to small and medium scale production lines.

The Two-Step method uses two separate machines. The preform is injection molded on the first, then reheated and blown on the second. The Two-Step system uses two separate machines: an injection molding machine for making the preforms, and a reheat blow molding machine to reheat the preforms from cold and blow the bottles. The requirement for a preform heating system means the Two-Step process has a lower thermal efficiency. This method is most suited to medium to large-scale production.

Acetaldehyde (AA) is a compound that exists naturally in many citrus fruits and other foods. It has a distinctive acidic taste. Acetaldehyde is also generated during the process of PET bottle manufacture.

With the growing popularity of PET containers, water companies are becoming more aware of AA and how it can affect product taste. In most cases, the flavour of AA is barely detectable during beverage consumption. Carbonated soft drinks, for example, have very sweet or tangy flavours that mask the slight taste of the plastic. But the very delicate, or even imperceptible, taste of pure water is not strong enough to mask acetaldehyde, and so it is easier for the consumer to notice the presence of AA. Consumers rank taste as the number one criterion when selecting a water brand. They look for purity that cannot be found in tap water. Water companies retain customer loyalty by delivering consistent, high quality products that fulfil the brand promise. Even minor differences in taste will compromise brand integrity and affect sales.

of which 30% are water bottles. Plastic makes up about 12% of all the municipal solid waste generated in the United States.

of which 30% are water bottles. Plastic makes up about 12% of all the municipal solid waste generated in the United States. of which 30% are water bottles. Plastic makes up about 12% of all the municipal solid waste generated in the United States.

of which 30% are water bottles. Plastic makes up about 12% of all the municipal solid waste generated in the United States.